The era of mass manufacturing certainly made a big difference to consumers. Whereas before, they had to wait for a home-based artisan to complete a product for them, mass manufacturers pooled resources in huge facilities and used economies of scale to drive down prices. The result was a vast supply of products of consistent quality and low prices: exactly what industrialists thought that consumers wanted.

But as time has worn on, it’s become increasingly clear that this is not what consumers want. Instead, people want customized products that have special meaning or reference to them. They don’t want to be like everybody else.

Technology, however, has been lagging consumer desires. It simply hasn’t been possible for companies to facilitate a high degree of customization because doing so would drive up the price of their goods too much – more than people are willing to pay. The only options until now have been partial customization – or “options” – or third-party aftermarket shops who specialize in customization, with the latter being very expensive for most products (like cars).

However, things might be about to change. Specific technologies are bringing the cost of personalization down to the point where it looks highly likely that we will soon enter an era of both mass-production and mass-personalization – something that has never happened in human history. Enabling technologies including things like additive manufacturing, lasers, generative design algorithms, and the sharing economy.

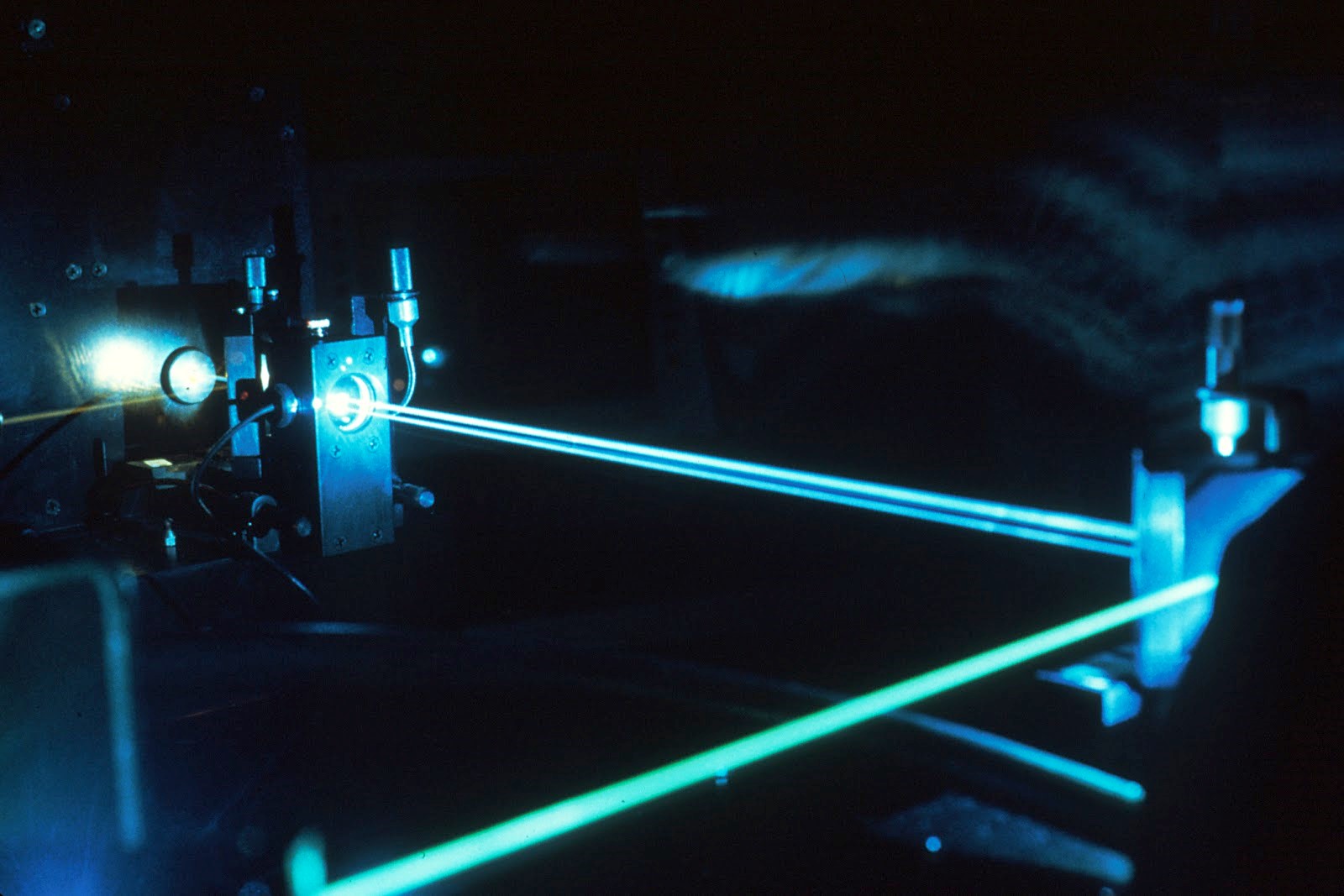

Laser Etching

Laser etching and removing laser etching are core technologies that will usher in the first wave of product personalization. In fact, lasers are finding applications in many industries already. The trick to greater personalization is to link laser etching methods to computer control systems so that lasers can automatically etch new designs from user instructions. For instance, a customer could log into a mobile phone website and then type text or upload images for a company to then automatically laser-etch the design onto the back of their phone. Not only would this bring down the cost, but it would also improve the customization of any product with a surface amenable to etching.

Consumers could also use etching methods to mark their products in unusual ways at the microscopic levels. Laser etching is so precise that it can etch details down to accuracies of three microns, or about the size of a human red blood cell.

Generative Design Algorithms

Another approach which could lead to more personalized products in the future is so-called generative design algorithms. Rather than a programmer sitting down and manually inputting all the details of a product, a generative design algorithm evolves a design based on the parameters set by the user. The design process takes place automatically in the computer as it tries to work out the optimal combination of shape, strength, material, weight, or whatever else the user specifies.

Although generative design algorithms sound complicated, in truth, they aren’t. These algorithms work in a similar way to evolution. After the computer creates each design, it subjects it to a series of tests based on the user input (like strength tests, for instance) and then makes a minor change to the design and starts the test all over again. The idea is that with each iteration, the design improves so that at the end of the process, you end up with a product that is ideally suited to a particular niche.

You can imagine consumers using this type of technology to meet their precise requirements. Consumers might need a new camera that is strong, flexible, and inexpensive. The generative design algorithm can then take those parameters and use them to craft the optimal product. What the consumer ends up with won’t be perfect, but it will get as close as it can to their material and budget requirements – perhaps closer than any mass-produced product today. The brand advantage could be substantial.

Additive Manufacturing

If businesses want to compete in the era of mass-personalization, they will need to master the major technology expected to make it all possible: additive manufacturing. Although additive manufacturing has been around since the 1980s, it’s only now that the technology is reaching maturity – the point at which dozens of industries could benefit from it.

Take businesses in the clothing industry. It’s expected that by the mid-2020s, additive manufacturing will have progressed to the point where we get “sub-micron” resolutions. At that point, it should be possible for 3D printers to print out items of clothing which look and feel like their conventional counterparts. However, additive manufacturing will make it possible to cheaply and quickly produce bespoke items of clothing that would cost thousands to make using traditional methods. Users could select from a variety of different options designed by other users or the company selling then clothes, or they could upload their own designs. Even more interestingly, companies could work with third-party clothes designers who upload designs onto the cloud for their clients.

Businesses in the prosthetics and sports industries also stand to gain from the additive manufacturing revolution. Many are already. Golf players, for instance, want clubs which perfectly conform to the shape of their hands. Additive manufacturing allows businesses to create ergonomic handles with bespoke designs for individual customers, without relying on generic molds. Prosthetics companies, such as those who manufacture hearing aids, can now benefit from 3D printing of ear molds rather than having to create custom molds for every customer.

Integration Of New Technologies

The most exciting companies won’t stop at a single technology to meet their customers’ needs: they’ll integrate all relevant technologies in a way that creates an incredible customer experience. For instance, a customer might not want to spend time designing their own product, even though they want something unique. As a result, they are most likely to choose companies with designs available on the cloud, or that use generative design techniques to produce something bespoke automatically. Finally, these products can be laser-etched at the micro- or macroscopic level to produce something truly unique and innovative.

Will your business start personalizing products soon to stay ahead of the competition?